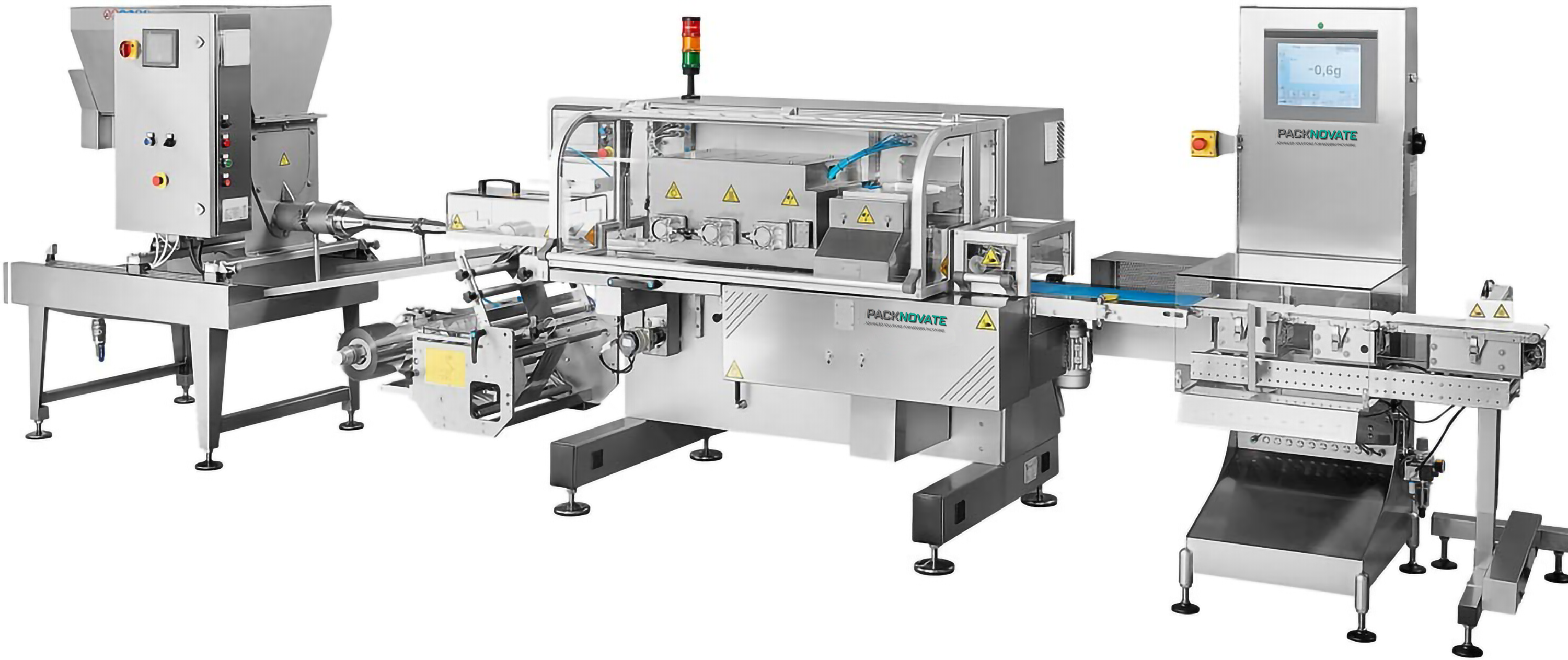

At Packnovate, we provide tailored solutions for the Molasses Tobacco industry. We offer primary line equipment, including bale separators, cutters, and mixers in various capacities and designs, as well as fully automatic systems. Our packaging machines support fully automated processes for Molasses Tobacco in a range of shapes and weights. We also provide full consulting on product design, addressing both engineering and market perspectives to enhance your product's success.

We offer high-quality packaging lines that guarantee product quality, reliability, safety, and flexibility.

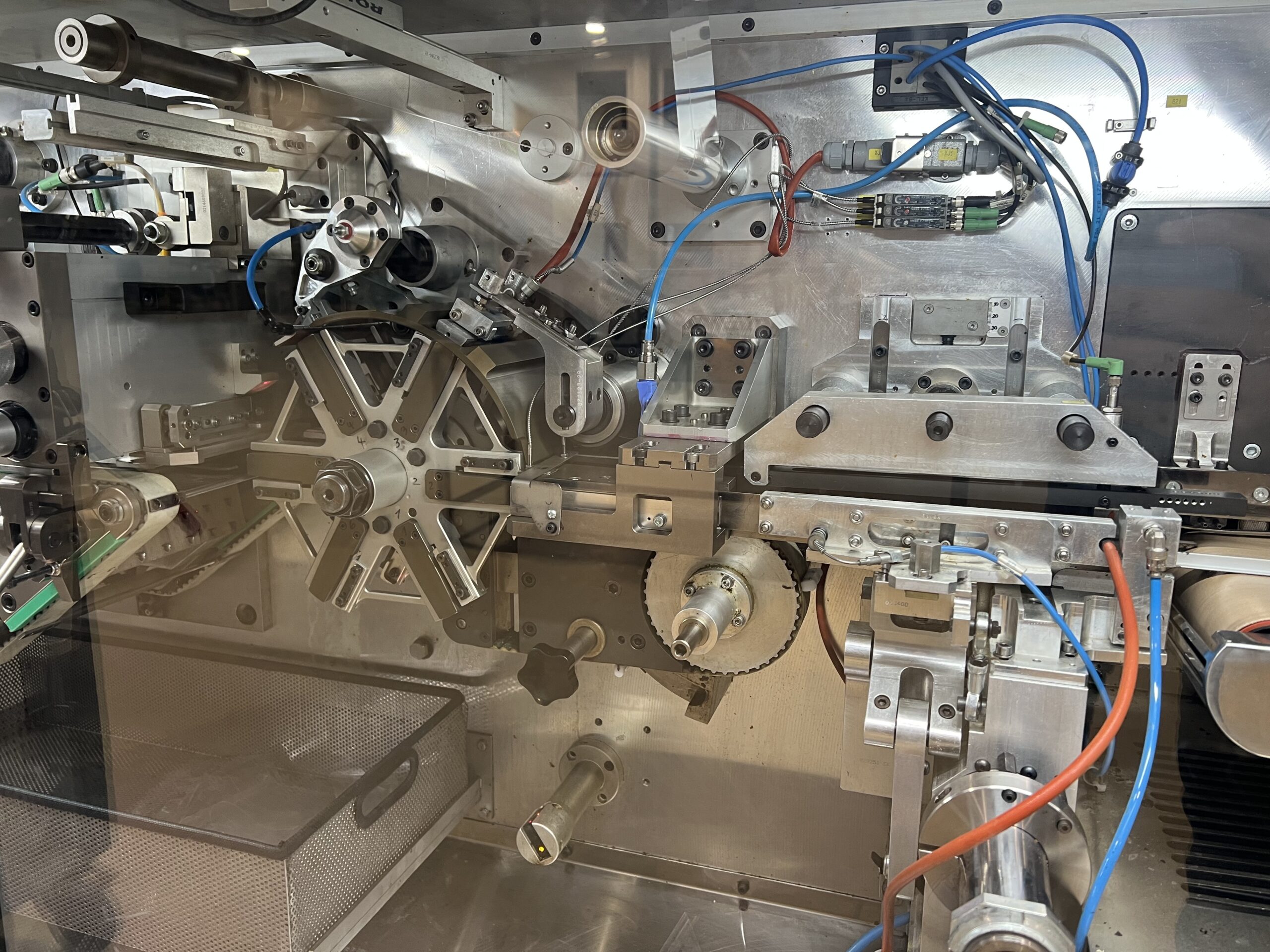

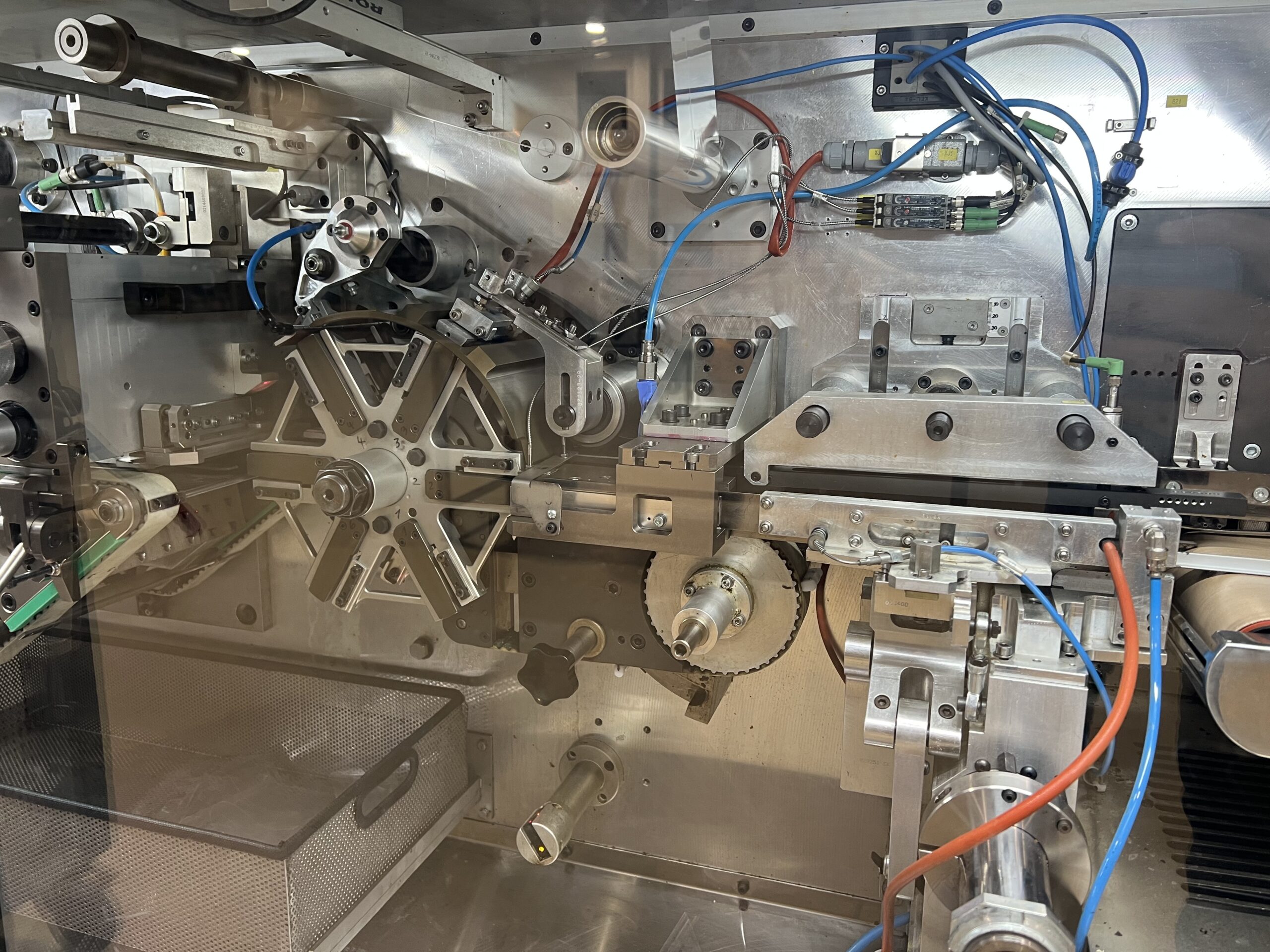

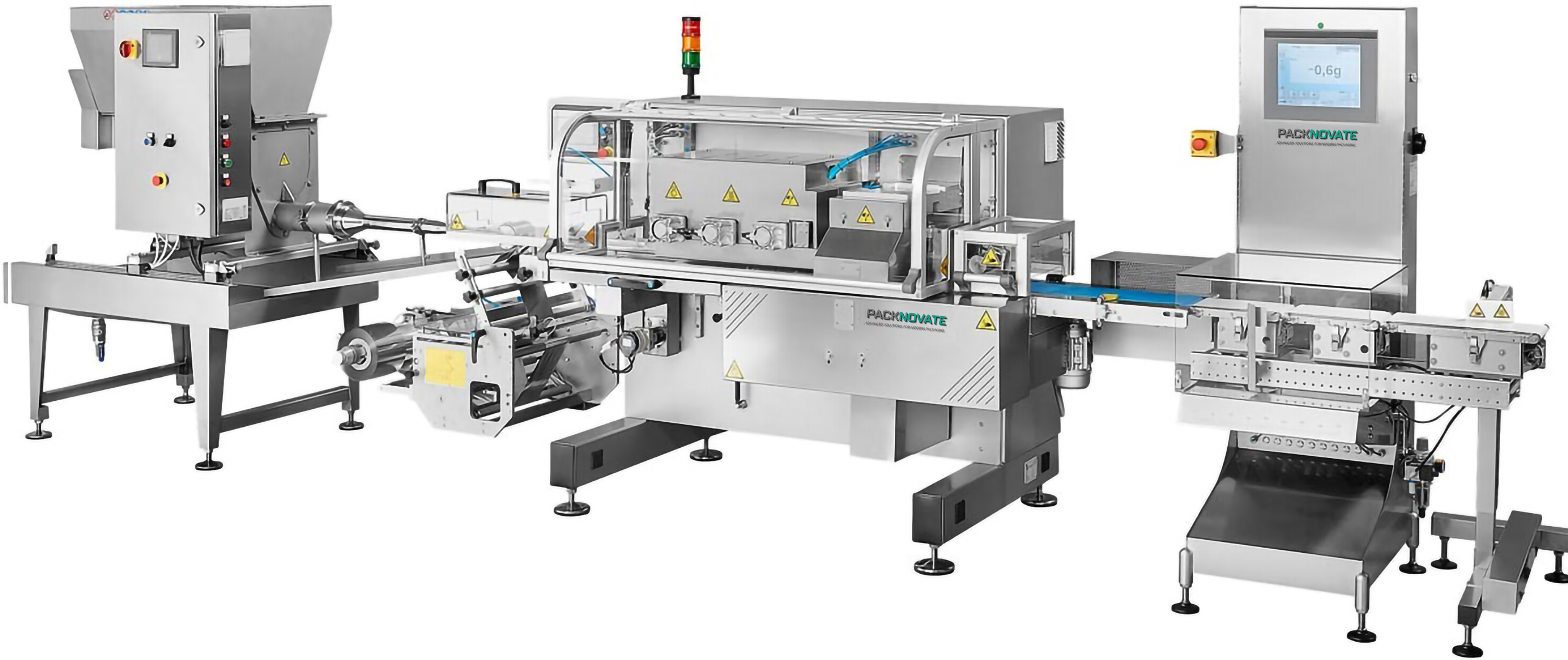

1. Dosing and Pouching Machines

Our dosing and pouching machines come in various capacities and speed with unique continuous mixing technique for even distribution of tobacco and liquids. They’re designed with advanced features for seamless, efficient production:

- Eye-mark detection: A photocell ensures that products are correctly positioned on the wrapping material to prevent jams in the transverse sealing jaws. Misplaced products are automatically allowed to exit, avoiding production stoppages for cleaning.

- Automatic dosing weight adjustment: Integrated with checkweighers.

- Easy cleaning, size changeovers, and flavor changes to keep production flexible and efficient.

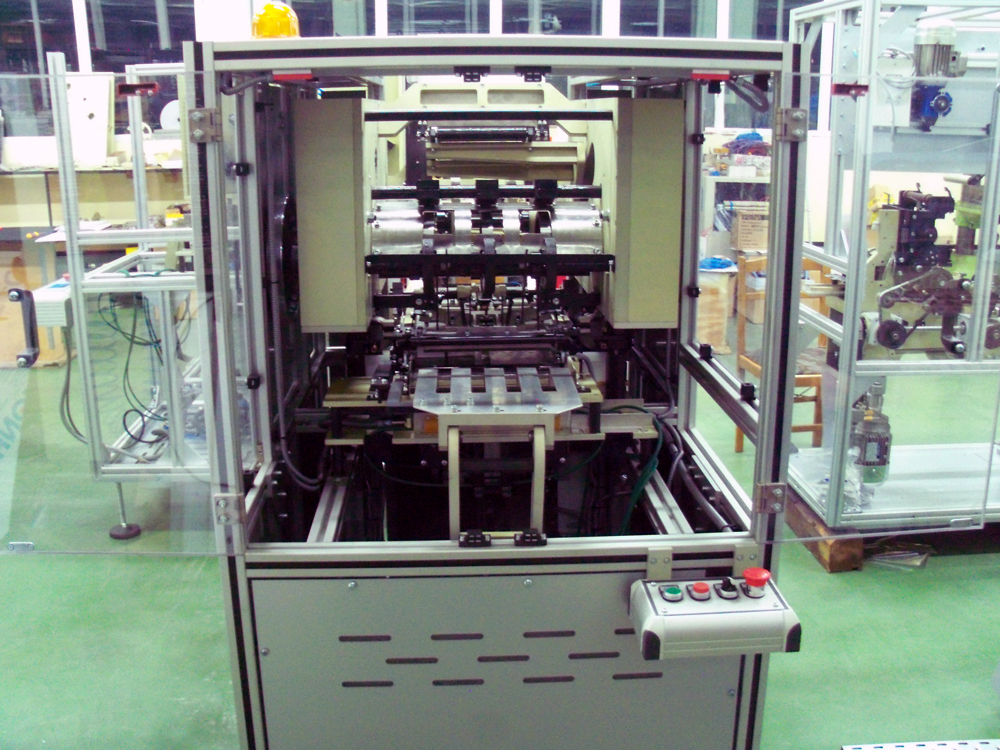

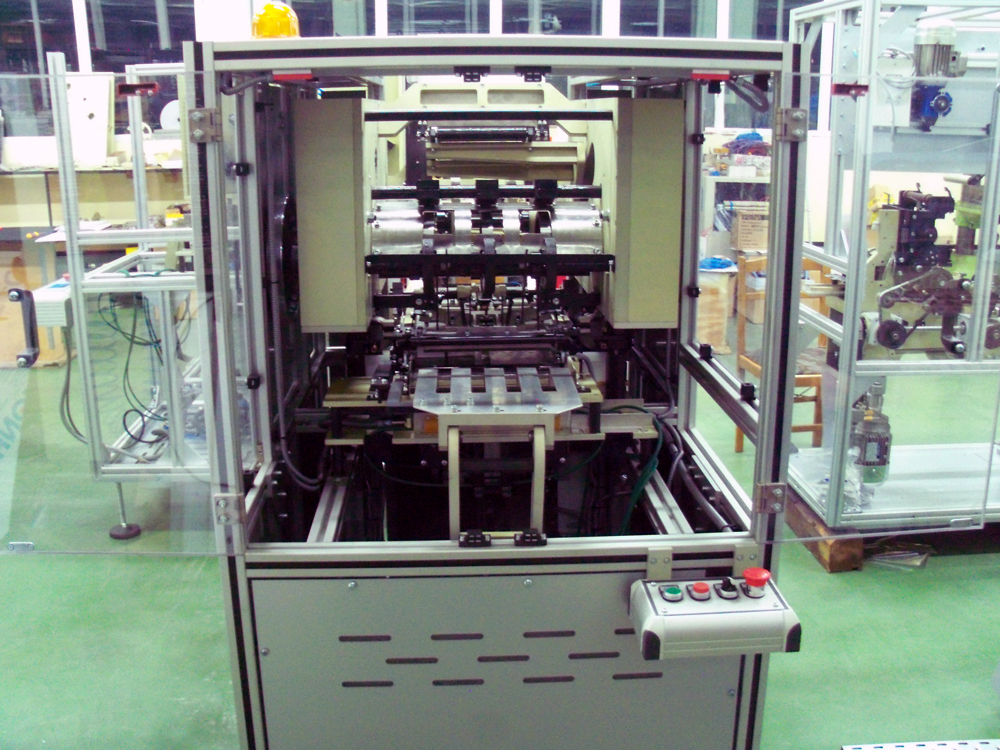

2. Cartoning Machine

At Packnovate, our Cartoning machines comes in different speed and for different size with features that include:

- Flexible carton-closing options, with or without hot melt

- Quick and easy changeovers supported by digital indicators for precise adjustments

- Integrated quality checks to detect

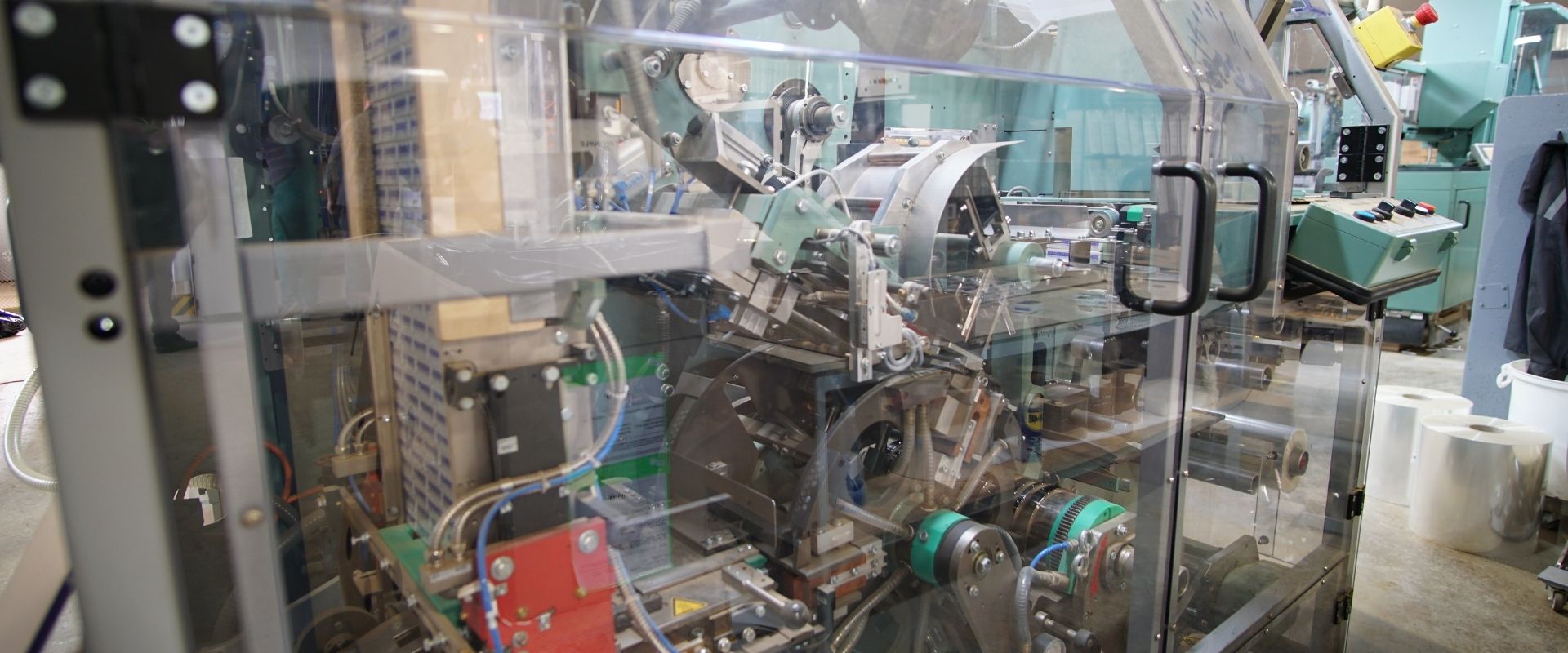

3. Cellophane Machine

Our cellophane machine is built with a robust construction and operates on a turret mechanism, ensuring excellent wrapping quality even at high speeds. Key features include:

- High-Quality Multi-Stage Sealing: Precision folder profiles and multi-stage sealing ensure excellent wrapping quality.

- Enhanced Final Finish: Ironing heaters on both the top and bottom carton faces deliver a tight finish and superior aesthetics for the final pack.

- Self-Adhesive Tear-Tape Unit: Equipped with a self-adhesive tear-tape unit for added convenience, allowing for easy opening of the final wrapped product.

- Quality Checks: Integrated quality checks verify the presence of cellophane and tear-tape, ensuring complete, accurately wrapped products.

4. Boxing Machine

At Packnovate, our boxing machine combines flexibility, reliability, and ease of maintenance. Key features include:

- Adjustable Gluing System: A flexible gluing unit enables precise glue adjustments for secure and efficient sealing.

- Accurate Pack Verification: Integrated quality checks ensure that all 10 packs are accurately placed inside each box before sealing.

- Heavy-Duty Design: Built for high performance and durability, with a design that allows for easy maintenance.

5. Overwrap Machine

Our cellophane machine is built with a robust construction and operates on a turret mechanism, ensuring excellent wrapping quality even at high speeds. Key features include:

- At Packnovate, we provide a highly reliable overwrapping machine equipped with an exit heat tunnel to ensure a high-quality finish for the final product. This design guarantees secure wrapping, precise sealing, and a professional appearance for every package.

OUR EXPERTISE INCLUDES

Our Molasses Tobacco Packaging Solutions Include:

We provide innovative packaging solutions tailored to maintain the integrity and quality of molasses and tobacco products. Our offerings are designed to support sustainability and enhance brand visibility, ensuring your products stand out in the market.

Airtight Seals:

Ensure long-lasting product freshness and quality.

Custom Designs:

Tailored packaging solutions to reflect your brand identity.

Tamper-Evident:

Secure packaging that builds consumer trust and safety.

Eco-Friendly Options:

Sustainable materials that reduce environmental impact.

Reliable Packaging for Molasses Tobacco Products

At Packnovate, we prioritize packaging that safeguards product quality while enhancing brand visibility. Our molasses tobacco solutions are tailored to your unique requirements, combining advanced technology with sustainable practices to meet industry standards. Trust Packnovate to deliver packaging that ensures safety and supports your brand’s success.

Custom Packaging Solutions for Molasses Tobacco

Packnovate specializes in creating innovative, tailored solutions for molasses tobacco products. From maintaining freshness to complying with regulatory requirements, our packaging systems are designed to protect your products and elevate your brand. Choose Packnovate for cutting-edge solutions that set your products apart in the market.

Why Choose Packnovate for Your Packaging Lines?

Packnovate offers cutting-edge packaging line solutions designed to meet the diverse needs of various industries. Our innovative systems ensure precision, reliability, and efficiency, helping you deliver professionally packaged products that stand out in the market. With a focus on quality, safety, and sustainability, Packnovate is your trusted partner for advanced packaging technology.

- Precision Engineering: Guarantees consistent and accurate packaging for every product.

- Flexible Solutions: Easily adaptable to different product types and packaging styles.

- Sustainable Practices: Eco-friendly materials and processes to reduce environmental impact.

- Enhanced Efficiency: Streamlined systems to optimize production and reduce downtime.

- Safety Assurance: Advanced features to ensure safe and secure packaging processes.

- Market-Ready Design: High-quality finishes that enhance product appeal and brand visibility.

WE CALL YOU BACK

Request a Call

LET'S TALK BUSINESS

Talk to a Specialist

Call us Now

Send an Email

HOW WE CAN HELP

Our Solutions

Delivering high-quality, high-speed primary and packaging lines for tobacco molasses, innovative solutions to enhance efficiency and quality in your current production lines. Our upgrades for obsoleted parts and adding advanced features, also we provide technical support, training, and spare parts supply, we ensure smooth operations.

Primary Lines

Fully automated to tobacco cutting, flavor and sauce addition,

and mixing to prepare tobacco for packaging.

Packaging Lines

Innovative solutions tailored for molasses

and tobacco packaging processes.

Spare Parts

High-quality spare parts ensuring consistent

performance and operational efficiency.